Project duration: 1 September 2019 – 31 December 2023

Objective

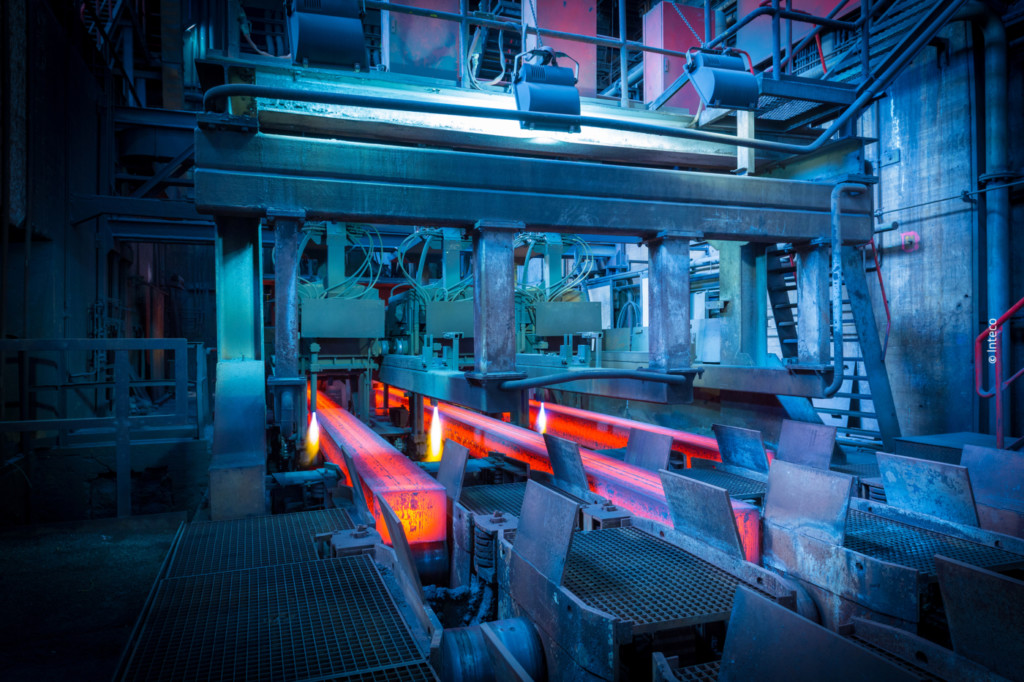

BATTERFLAI is a sustainable and efficient flotation process for the recovery of battery metals, using abundant resources for environmental friendly flotation reagents that can secure the supply and quality of collectors for the smooth operation of the mines. The new collectors have unique properties regarding the suppression of iron during flotation and selective recovery of battery base metals such as Cu, Ni, Co and Au from sulphide iron ores.

The solution (technology)

As copper (Cu), nickel (Ni) and cobalt (Co) are three of the main components of the cathode of Li-batteries, rising demand from the battery sector will “have a disruptive impact” on their markets over the next 10 years. We expect copper demand from electric vehicles to rise from 208k tonnes in 2017 to 1.91m tonnes in 2030; i.e. a 19% annual increase. Moreover the annual nickel demand for lithium-ion batteries may rise to more than 190 000 metric tons by 2030 from about 5 200 tons in 2016 and cobalt will increase roughly by 450% from the same year to 2025. Gold is not currently used as a component in Li-ion batteries, however it has been suggested as a potential cathode material or LiMn2O4 coating due to its high volumetric capacity and power density. In contrast to falling supply, the gold demand is pro-jected to grow, especially when it comes to technology demand.

BATTERFLAI offers a sustainable and efficient flotation process for the recovery of base metals, such as Cu, Ni, Co and Au, needed for the manufacturing of Li-ion batteries from sulphide iron ores that com-pared with the current industrial practice of flotation, uses lower-carbon footprint, biodegradable and more environmental friendly reagents obtained from underutilized forest residues or side streams from the forest industry. One specific characteristic of the new flotation collectors is that they supress the flotation of non-valuable iron sulphide minerals such as pyrites or pyrrhotite Moreover, due to the need of importing flotation collectors, European mines have faced supply and quality issues. BATTERFLAI, using European resources for the production of flotation reagents, can secure the supply and quality of collectors for the smooth operation of the mines.

The BATTERFLAI project has a strong scientific base in the project research partners, i.e. Luleå University of Technology, RISE Research Institute of Sweden and National Technical University of Athens, and is organized along the value chain through Boliden, KGHM Cuprum, KGHM Polska Miedz S.A., IMN, Hellas Gold, ColloidTek and LTU Business to support the scaling up of a lignin based flotation concept, contributing towards an expanding circular economy and new business opportunities within and outside Europe.

Partnership

- Boliden Mineral AB, Sweden

- ColloidTek Oy, Finland

- Geological Survey of Finland, Finland

- HELLAS GOLD S.A., Greece

- Institute of Non-Ferrous Metals, Poland

- KGHM Cuprum Ltd. Research & Development Centre, Poland

- KGHM Polska Miedz Spólka Akcyjna, Poland

- LTU Business AB, Sweden

- National Technical University of Athens (NTUA), Greece

- RISE Research Institutes of Sweden AB, Sweden

- Luleå University of Technology (LTU) (Lead Partner), Sweden