Growing market for electric vehicles will create a massive recycling need

The EIT RawMaterials new innovation project ReLieVe (Recycling Li-ion batteries for electric Vehicle), developed by EIT RawMaterials industry partners Eramet, BASF and SUEZ, will receive funding of €4.7 million. The objective is to develop an innovative closed-loop process to recycle lithium-ion batteries from electric vehicles and to enable the production of new lithium-ion batteries in Europe.

The project will kick off in January 2020, and over a two-year period, ReLieVe will carry out a series of activities for the large-scale development of this innovative process and the structuring of an integrated industrial sector: from the collection and dismantling of end-of-life batteries going into recycling all the way to the manufacturing of new electrode materials.

The collaboration along the value chain supports an efficient and integrated approach. The industrial members of the project are leaders in their sector and are ideally placed in the value chain: SUEZ for collection and dismantling of end-of-life batteries; Eramet for the development of the recycling process; and BASF for the manufacturing of cathode active materials. Connecting with partners across the EIT Knowledge Triangle, the Academic researchers from Chimie ParisTech and the Norwegian University of Science and Technology (NTNU) will support the industry partners to accelerate the search for innovative solutions. The industrial members will also be backed by the automotive sector that will be part of the advisory committee.

The development of new European lithium-ion battery recycling capabilities will make it possible to respond to the strong growth of this market in the coming years and to the issue of securing Europe’s supply of raw materials required for its energy transition. Moreover, the virtuous recycling process meets the essential challenges of sustainable performance through its savings on raw materials.

The recovery of nickel, cobalt, manganese and lithium elements into battery-quality products is at the center of Eramet Group’s current R&D developments.

The ReLieVe project responds to the European Commission’s appeal to unite European players to position itself in the fast-growing lithium-ion battery market. Thanks to the funding provided by the EIT RawMaterials, the ReLieVe project will be able to accelerate its work and progress towards the construction of a lithium-ion battery recycling sector with an innovative and competitive process on a European scale.

Laurent Joncourt, Chairman of Eramet Ideas, the Group’s R&D Center

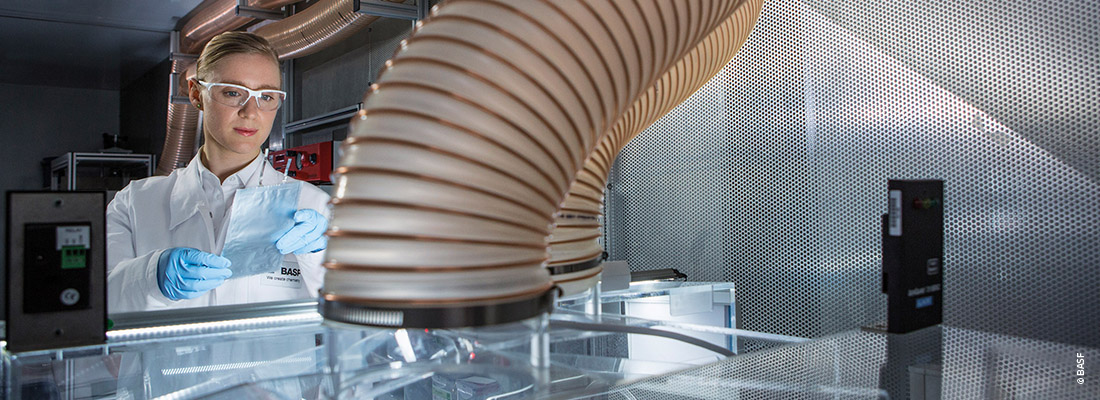

As a leading cathode active material supplier to battery producers for electrified vehicles, BASF is confident that recycling will play an increasingly important role in the roll-out of electromobility. We are committed to foster an innovative, sustainable and competitive battery value chain in Europe together with partners and will contribute our expertise in cathode material production to the project.

Daniel Schönfelder, Vice President of Business Management, BASF Battery Materials Europe

We are proud to bring our expertise and contribute to the recovery of end-of-life battery components through this partnership. Around 50,000 tons of batteries are expected to be recycled by 2027 in Europe and it could be multiplied almost tenfold by 2035. With the ReLieVe project, SUEZ is supporting the development of alternatives approaches that blend circular solutions with sustainable urban mobility.

Jean-Marc Boursier, SUEZ COO and Senior Executive VP Group in charge of Northern Europe and IWS Europe