Objective

Based on a need for raw material solutions for a sustainable European mobility industry, PhD students are trained in the CE COSP course. As future experts in manufacturing and material science they develop a circular perspective, innovation competence and an entrepreneurial mindset focussing on the recyclability of new materials.

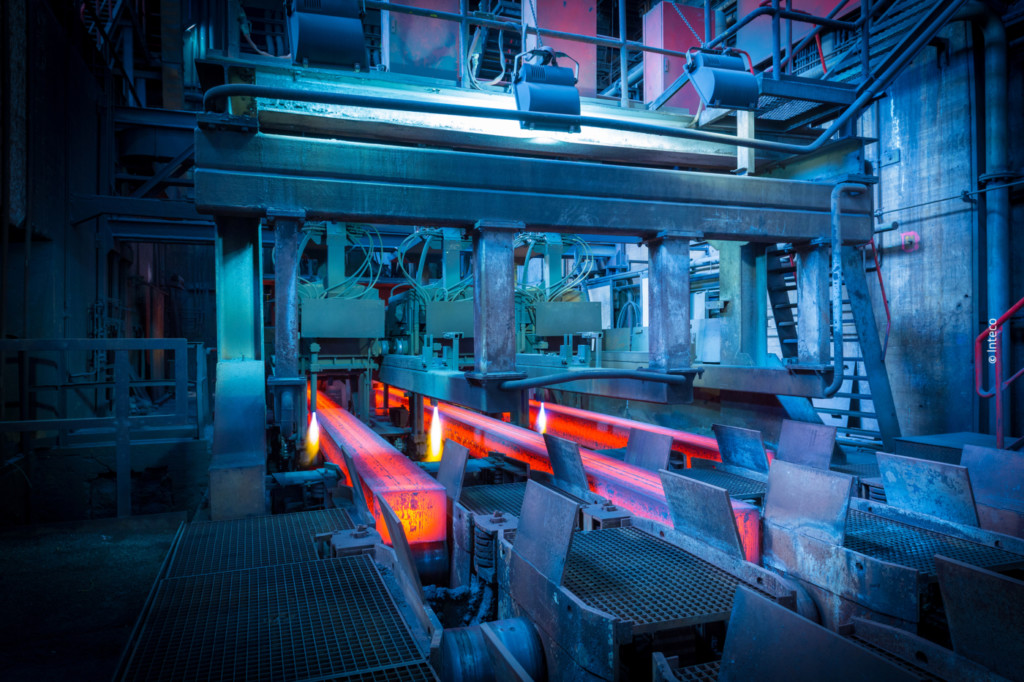

The course combines blended learning with practical periods in industry and training on entrepreneurship and innovation. Currently a lot of innovation is ongoing in the use of very light materials for the automotive industry. But there are nearly no technologies to recycle this new materials at the moment. PhD students from engineering, manufacturing and material sciences on the one hand, and economists on the other hand, are trained together in this interdisciplinary course to develop an awareness of the recyclability of materials used in the mobility sector, and foster innovation and entrepreneurial activity in this field.

The solution (technology)

The course is based on innovative elements including blended learning and constructivist methods. In CE COSP, doctoral students will be given the opportunity to reflect and adjust their research to better contribute to the transformation to a more resource efficient and circular utilization of primary and secondary raw materials. Furthermore, via clear the integration of the entrepreneurial mindset there is an opportunity for the contribution of the attendees to green growth in Europe.

Sustainable production relates to among other aspects; raw material efficiency, circularity, toxic free technologies and costs. In order to achieve positive environmental gains, such aspects have to be considered holistically. In practice this means that the use of raw materials in production downstream has to be managed carefully. It is a prerequisite to sustainable management to have relevant knowledge about raw materials. The course CE COSP therefore provides attendees with both theory and practical competence in raw materials using constructivist teaching. The course materials will spread out at least to all interested EIT Raw Materials partners to multiply the benefit and secure a sustainable use.

Partnership

Swerea IVF AB, Sweden (Lead Partner)

ArcelorMittal Eisenhuettenstadt, Germany

Boliden Mineral AB, Sweden

Höganäs AB, Sweden

Interessensgemeinschaft der Recycling- und Entsorgungsunternehmen e.V. (FIRE e.V.), Germany

Kungliga Tekniska Högskolan (KTH Royal Institute of Technology), Sweden

Mälardalen University Bjelkemyr, Sweden

RISE Research Institutes of Sweden AB, Sweden

Swerea MEFOS AB, Sweden

Tallinna Tehnikaülikool (TTÜ Tallinn University of Technology), Estonia

Technische Universität Bergakademie Freiberg (TUBAF), Germany

For more information, please visit the project web page.