How a Startup is Tackling the Looming Solar Panel Waste Crisis

Ever since photovoltaic (PV) panels were mass-produced and installed in the early 2000s, solar energy has become a key form of renewable energy. Its ability to generate electricity without emitting direct greenhouse gases has made it crucial in combating climate change. However, a significant issue has gone largely unnoticed: solar panel waste.

Because PV panels have a life expectancy of about 25-30 years, we are on the verge of a significant influx of panels reaching the end of their lifecycle. As the demand for solar energy continues to grow, this could lead to an estimated 60 million tons of PV panel waste in landfills by 2050.

9-Tech is turning this challenge into an opportunity. The Venice-based startup has developed a groundbreaking process to upcycle PV panels into valuable raw materials.

“To me, it makes no sense to see these raw materials, which cost a lot of energy, time, and effort to be extracted, purified and modified, go to landfills”, said Pietrogiovanni Cerchier, Materials Engineer and CEO of 9-tech. “Upcycling these materials not only conserves resources but also reduces the environmental impact of raw material extraction and transportation. ”

Challenging the Status Quo

9-Tech began as Cerchier’s PhD project at the University of Padova, Italy, as part of ReSiELP, an EIT RawMaterials-supported upscaling project focused on recovering silicon and other materials from end-of-life PV panels. Using expertise gained from ReSiELP, Cerchier founded 9-Tech in 2020 to develop a more efficient and cost-effective recycling process.

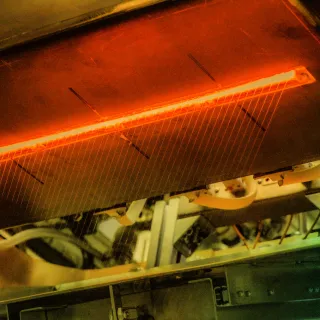

Their innovative solution, combining thermo-mechanical treatment, offers an alternative to current industrial-scale recycling methods that mainly involve removing the aluminium frame and wiring and shredding the glass, while other more valuable materials like silver and silicon are discarded.

Results at 9-Tech’s pilot plant in Venice have been promising: the process can recover 90% of the silver, 95% of the silicon, and nearly 100% of the copper, aluminum, and glass from a PV module. Moreover, it yields highly pure materials, making them more suitable for reuse.

The process has also demonstrated low energy consumption, comparable to existing mechanical treatments, and does not produce hazardous wastewater, making it a viable and environmentally friendly alternative.

Navigating Challenges with EIT RawMaterials Support

There were no shortage of challenges along the way. “We had to develop three prototypes before successfully performing the actual separation between the PV cells and the glass,” Cerchier explained. The team also designed custom equipment for the chemical treatment, which required extensive testing. This innovation has been costly, and for a startup like theirs, initial funding from EIT RawMaterials has been vital.

The company in 2020 received a €40,000 grant from EIT RawMaterials’ Booster Programme and an additional €45,000 from the Accelerator Programme. “Thanks to the initial fundings, we were able to design and realise the pilot plant for testing,” Cerchier said.

The company has also leveraged EIT RawMaterials’ extensive network and expertise in the raw materials sector. Since 2023, 9-Tech has been tasked with coordinating the Parsival Project, a European RIS Capacity Building initiative funded by EIT RawMaterials, aimed at enhancing PV panel recycling knowledge and innovation.

At the Innovation Village during the Raw Materials Summit this May, 9-Tech showcased their solutions to nearly 1,000 participants from the broader raw materials community. “These opportunities are expanding our network and visibility. They enable us to connect with customers and collaborate with research centers within the raw materials sector,” Cerchier said.

The Future: Industrial Scale-Up

The company is gaining recognition for its groundbreaking innovation.

In 2022, 9-Tech won the first prize (€250,000) in the ESG Climate Call organised by Intesa SanPaolo Vita and Fideuram Vita. In 2023, it received the “Change the World” award from Fortune Italia, dedicated to the most innovative startups in the sustainability sector. The company currently owns two EU patents on photovoltaic recycling and has filed four more.

With the success of the pilot plant, the focus now shifts to scaling up to an industrial level. 9-Tech has entered a joint venture with Veritas and Haiki Mines and applied for authorization for an industrial plant this year. The project has also attracted €600,000 in co-funding from the Italian Ministry of Environment.

Although it took 15 months for 9-Tech to receive the permit for their pilot plant, the startup is hopeful to overcome this hurdle as they have with many others. If approved, the industrial plant will significantly increase operations from the pilot plant to a capacity of up to 700 modules a day. This translates to more than 4,000 tons of recycled modules a year.

“We cannot sustain endless extraction of raw materials, which are finite. Recycling is not just necessary; it is essential for a sustainable future,” Cerchier said.

The Raw Materials Summit 2024 was organised by EIT RawMaterials, the world's largest network in the raw materials sector. The next Summit will take place from 13 to 15 May, 2025, where topics related to investment, innovation, and the circular economy will be explored. https://eitrmsummit.com/