AM 4 AM: Reshaping the future of 3D metal printing

AM 4 AM, an advanced materials startup from Luxembourg supported by EIT RawMaterials, has developed the strongest aluminium alloy on the market: HiperAl

3D printing is revolutionising manufacturing processes with its ability to create lightweight, custom-designed parts on demand, making it a key technology for industries like aerospace and automotive. With the market projected to expand at an impressive annual rate of nearly 19% through 2030[1], 3D printing is poised to play a central role in the future of these industries.

However, 3D printing relies on high-quality metal powders, which presents both a challenge and an opportunity for Europe. The continent’s reliance on imported raw materials creates vulnerabilities in securing a stable supply, especially as global demand for critical raw materials continues to rise.

Advanced materials offer a way forward by substituting at-risk raw materials - improving product performance, reducing weight and enhancing energy efficiency while strengthening Europe’s supply chain resilience, and maintaining its competitive edge.

AM 4 AM is a startup addressing these challenges by enhancing the performance of metal powders for additive manufacturing while prioritising the development of a European supply chain.

A triple threat in additive manufacturing

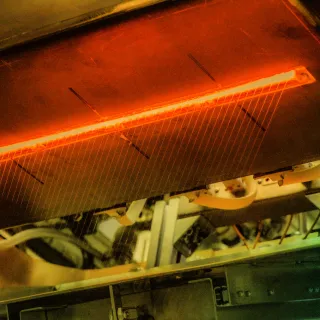

Short for Advanced Materials for Additive Manufacturing, Luxembourg-based startup AM 4 AM has developed a new cold plasma technology that enhances conventional metal powders, making them stronger and more adaptable. Their eco-friendly process uses only 2 kW of energy per hour and operates solely on nitrogen gas, removing the need for harmful chemicals.

AM 4 AM’s patented atmospheric cold plasma treatment evenly distributes ceramic particles on the surface of metallic powders, significantly improving their properties and processability. This creates a dense, crack-free microstructure that enhances durability and reliability, making it ideal for applications in the automotive, aerospace, and space industries.

Using this technology, the company has created HiperAl - an advanced aluminium alloy specifically designed for additive manufacturing. HiperAl delivers outstanding mechanical performance, surpassing both wrought components and parts made with traditional powders, especially under high temperatures. It also supports industrial-scale applications and offers weight reductions of up to 70%.

Currently, AM 4 AM is focused on producing aluminium alloys, which are in high demand across Europe. Unlike traditional alloys that rely on scandium - primarily sourced from regions like Russia, China, and Kazakhstan - AM 4 AM’s alloys use zirconium, a material that can be sourced from recycled nuclear waste within Europe.

Beyond its technical and environmental capabilities, AM 4 AM also supports the European critical raw materials supply chain. By sourcing and manufacturing regionally, the company is clear evidence of European policy in action, helping startups in the sector set up sustainable and responsible operations.

“I believe it’s crucial to deeply understand and analyse the origins of the materials we use - their roots, how and where they are produced, and the impact of transporting them,” says Maxime Delmée, AM 4 AM’s CEO and Founder. “The time of launching products without considering where materials come from is over. For any entrepreneur entering the raw materials space, I’d say: start by understanding where your supply chain starts.”

Attracting customers with high-quality products

Backed by EIT RawMaterials, AM 4 AM recently raised €1.3 million in seed funding to fuel its next phase of growth. The funding will support the launch of a state-of-the-art production facility in Luxembourg, set to open by early 2025, and allow the company to bring an experienced business developer on board.

The new facility will expand the production capacity of its enhanced metal powders and accelerate the development of high-quality materials to meet the high standards of customers in the aerospace and automotive industries.

“With the platform we have now and the factory we’re building, we’ll be able to speed up the process of getting new products to market. Our target customers need very high-quality products and that is what we are focused on delivering, as fast as possible,” says Maxime.

Maxime Delmée, AM 4 AM’s CEO and Founder at their headquarters in Luxembourg

A rapid journey: from concept to production within 5 years

In just five years, AM 4 AM has grown from an idea to a company running its first production facility - an impressive feat considering the challenges of running a new startup during a pandemic.

AM 4 AM began to take shape during founder Maxime’s PhD research at the Luxembourg Institute of Science and Technology (LIST), where he specialised in plasma treatments, nanoparticle synthesis, and surface modification. During his research, he observed a unique phenomenon in the plasma phase, which sparked the idea for a novel approach to material enhancement.

Struggling to find employment after completing his PhD, Maxime decided to channel his expertise into the emerging field of additive manufacturing. He revisited the observations he made during his PhD and developed an innovative cold plasma process to improve the performance of metal powders. By April 2019, Maxime had filed the patent for the technology, and three months later he founded AM 4 AM.

EIT RawMaterials role in the funding of the project

Securing funding is one of the biggest challenges for any startup, and AM 4 AM was supported by EIT RawMaterials in connecting with European innovation and technology funding ecosystems. The European Commission’s Horizon 2020 programme provided the crucial funding for their initial proof of concept, followed by backing from Luxembourg’s Fit 4 Start initiative and the EIT RawMaterials Accelerator Programme.

“The EIT RawMaterials Accelerator Programme was very valuable for us”, says Maxime. “It’s boosted our network, and the coaching really helped us refine our structure and define our target market. The workshops are still ongoing, and the coaches continue to give us great support.”

EIT RawMaterials has also been proud to support AM 4 AM’s journey. “It’s been a real pleasure to work with AM 4 AM and help bring this innovative technology to market,” says Nicolas Menou, Business Development Manager, EIT RawMaterials. “Their cold plasma technology unlocks new applications for additive manufacturing at an industrial scale - it’s eco-friendly and enhances the mechanical properties of printed metal parts while improving the resilience of the raw materials supply chain. AM 4 AM’s combination of technical innovation and commitment to sustainability makes them a standout in the field.”

Expanding applications and markets

The latest €1.3 million funding round marks the start of a new chapter for AM 4 AM. With proof of concept, product launch, and MVP (minimum viable product) definition behind them, the company is now focused on scaling operations and transitioning into a fully-fledged industry player. “The new funding allows us to move beyond the initial phase and focus on real growth,” says Maxime.

While the powder is already commercially available and has attracted pilot customers, the company is now working to meet the industry’s stringent quality standards and expectations. This funding will enable AM 4 AM to improve the maturity of the HyperAl product and scale up production. Their new production facility, aiming to be operational by Q1 2025, will provide the capacity and efficiency needed to meet growing customer demand.

Looking to the future, AM 4 AM plans to leverage the versatility of its technology to develop powders with other metals, such as nickel and copper, broadening its applications and potential impact.

While their current focus is on the European market and helping strengthen the regional supply chain, AM 4 AM has also seen strong interest from international partner nations including the United States, Taiwan, and Japan.

Want to know more about how EIT RawMaterials can support your startup or idea?

Use our contact form to reach out. Find more funding opportunities here.

Background Information:

MVP: In this context, AM 4 AM’s MVP refers to the initial, market-ready version of its HyperAl aluminum powder, designed to demonstrate its technology’s potential while still leaving room for further development and refinement.