Progressing European Strategic Projects: A Landmark Molybdenum Offtake for Europe’s Green Steel Supply Chain

A 10-year, $1.6 billion molybdenum offtake agreement between Greenland Resources and Outokumpu marks a major milestone for securing Europe's green steel supply chain and industrial resilience.

Earlier this year, Europe took an important step toward securing its stainless-steel supply chain with the signing of a 10-year, US$1.6 billion molybdenum offtake agreement between Greenland Resources and Outokumpu, Europe’s largest stainless-steel producer.

Facilitated by EIT RawMaterials-led European Raw Materials Alliance (ERMA), this agreement marks a major milestone in securing Europe's supply of critical raw materials and strengthening its industrial resilience.

Ruben Shiffman, Executive Chairman, Greenland Resources, emphasised the collaborative effort that made this agreement possible: "This teamwork was essential, and we couldn't have done it without Outokumpu, the government and people of Greenland, EIT RawMaterials, and the European Commission.”

Why this agreement matters now

Green steel – low-emission steel produced with clean energy and responsibly sourced raw materials – is central to Europe’s green transition. It is the foundation for future infrastructure: from renewable energy and clean transport to construction, defence and digital technologies.

Europe’s ability to produce green steel, particularly high-strength and corrosion-resistant grades, depends on securing alloying elements such as chromium, nickel and molybdenum, with molybdenum playing a critical role in strength and corrosion resistance.

Europe is the world’s second-largest consumer of molybdenum, but it currently has no domestic production – a strategic vulnerability at a time when global demand for critical minerals is rising sharply.

The Malmbjerg project in central-east Greenland, developed by Greenland Resources, will change that. Expected to be operational within the decade, the mine will produce 32.8 million pounds of molybdenum annually, with Outokumpu receiving 8 million pounds per year, meeting nearly half of its demand. Thanks to its low impurities, Malmbjerg’s molybdenum is ideally suited for high-grade steel alloys.

“Securing extraction and access to molybdenum that is both sustainable and cost-competitive within the EU, is a major step forward for Europe and an example of how critical minerals for Europe from Europe are possible,” said Marc-Simon Schaar, Chief Procurement Officer at Outokumpu.

Beyond its economic and social significance, the agreement has strategic significance for Greenland and the growing EU-Greenland partnership.

Outokumpu’s commitment to sustainable European industry

With production facilities in Finland, Germany, and Sweden, Outokumpu is a cornerstone of the continent’s industrial base.

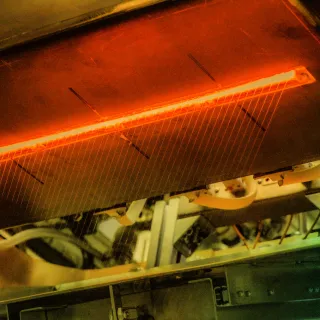

Outokumpu already produces stainless steel with the lowest carbon footprint in the global industry – up to 75% lower than average – thanks to its use of over 90% recycled material, low-carbon electricity, and integrated ferrochrome production from its Kemi Mine in Finland, the EU’s only chromium mine.

“The high-quality molybdenum ore at Malmbjerg will secure Outokumpu’s supply chain, and in turn, allow us to maintain a consistent, long-term supply of specialty steel products. The low-emission molybdenum from Greenland Resources Inc. supports in further decarbonising Outokumpu’s production and continuing our long-term strategy for sustainable and cost-competitive value-chain integration,” Schaar added.

Ruben Shiffman, Executive Chairman, Greenland Resources Inc.,

speaking at the EIT RawMaterials in May, 2025.

Marc-Simon Schaar, Chief Financial Officer, Outokumpu Corporation,

speaking at the EIT RawMaterials in May, 2025.

Partnering for sustainable supply chains

The Malmbjerg project is built on a strong Environmental, Social, and Governance (ESG) framework. Its mine design prioritises reduced water usage, minimal aquatic disturbance, and a low environmental footprint. Once operational, Malmbjerg is projected to become Greenland's largest revenue-generating venture, potentially injecting close to US$100 million in taxes annually for 20 years at current market prices. Beyond its financial contribution, the Malmbjerg project will support skills development, improve infrastructure, and boost local employment, driving long-term industrial growth in Greenland.

Shiffman stressed the importance of working with like-minded partners like Outokumpu that prioritise people and local impact: “In our early talks with Outokumpu, their first questions weren’t about the metal, but about the people of Greenland. Do they have access to education, healthcare, and a good life? That’s the kind of partner we want.”

“For us, sustainability goes beyond CO₂ emissions,” Schaar said. “It includes geopolitical alignment with like-minded countries and a deep respect for human and social factors. Our cooperation with Greenland Resources reflects this shared commitment.”

Read more on how EIT RawMaterials supports Greenland Resources.

For more information about Greenland Resources, visit greenlandresources.ca.

For information about Outokumpu, visit outokumpu.com.