MagREEsource: Securing Europe’s Rare Earth Magnet Supply Chain

French deeptech startup MagREEsource is creating Europe’s first major supply of fully recycled rare earth magnets, boosting industrial resilience while cutting emissions.

Permanent magnets made from rare earth elements are a cornerstone of the energy transition. They power electric vehicles, wind turbines, robots and a range of defence and aerospace systems. Yet Europe’s supply of these critical elements comes almost entirely from China, leaving its industries dangerously exposed to price volatility and supply chain disruption.

French deeptech startup MagREEsource aims to change that. Supported by EIT RawMaterials, MagREEsource recently raised €23 million to scale up its first factory and production of 100% recycled rare earth magnets, using a process that drastically cuts CO₂ emissions and sources its raw materials from end-of-life products across Europe.

It is now preparing to launch its second site, MagFactory, which will be Europe’s first large-scale facility for sustainable permanent magnets. Scheduled to open in 2028 and recognised as a Strategic Project under the EU Critical Raw Materials Act, MagFactory will have the capacity to produce up to 1,000 tonnes of magnets per year, covering a significant share of Europe’s current needs.

From research to industrial production

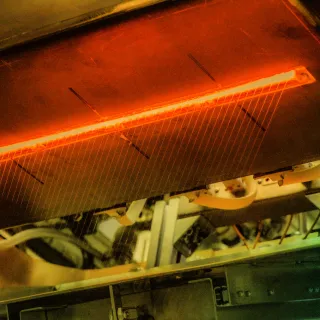

Founded in 2020 as a spin-off from CNRS (France’s National Centre for Scientific Research), MagREEsource was built on more than 25 years of research into making magnets from rare earth elements. Sophie Rivoirard, Vice President for Technology, Co-founder, and Erick Petit, President and Co-founder, developed a breakthrough “short-loop hydrogen” process that uses hydrogen to separate and recover magnetic alloys from end-of-life products – avoiding energy-intensive acid leaching or mining new ore. The process reduces chemical waste, energy use, and CO₂ emissions by up to 91%, while preserving the quality of the recovered material so it can be reused directly to make new magnets.

MagREEsource sources feedstock from end-of-life products from Waste Electrical and Electronic Equipment (WEEE) recycling streams, including end-of-life vehicles and dismantled wind farms from across Europe.

But taking this technology from the lab to full-scale industrial production required investment, infrastructure, and validation, which is where EIT RawMaterials came into the picture. In 2021, EIT RawMaterials invested €260,000 in MagREEsource’s first financing round, enabling the company to develop initial dismantling technologies for WEEE scraps before these materials entered the industrial magnet-making process.

“Our connection with EIT RawMaterials is not just about financing a new technological development,” Petit said. “It’s also about networking with public authorities and major European industries. We are working together on new EU regulations and promoting R&D within consortia across EU territories. And as every startup constantly needs new funds, we can say that their support clearly reinforced our credibility with other investors.”

The company has since filed three patents, with more planned for 2025-26, and is the only manufacturer worldwide producing 100% recycled magnets to the same technical standards as magnets made from virgin materials.

Building capacity for Europe

In December 2024, MagREEsource opened its first magnet production site in Noyarey, France, with an annual capacity of 50-80 tonnes. Around two-thirds of its 50-person team focuses on production, with the remainder driving R&D and the creation of new European standards for magnet quality and traceability.

The recent €23 million funding round will allow MagREEsource to expand its current production capacity, industrialise its second technology: the “short-loop fusion” process. This is an advanced metallurgical process that uses foundry techniques to further purify recycled materials, enabling entry into markets with demanding performance standards. The funding will also support the launch of MagFactory, which will produce up to 1,000 tonnes per year to cover roughly 10% of Europe’s current magnet imports from China.

MagREEsource has already secured a pipeline of orders worth €2.5 million and signed offtake agreements with major automotive and industrial customers, including French pro-audio leader L-Acoustics, which invested in the company’s latest fundraising round. “For L-Acoustics, having a stable European supplier safeguards the heart of its product range while supporting innovation in sustainable magnet technologies,” explained Petit.

A European vision

Beyond meeting customer demand, MagREEsource is positioning itself to be a pillar of European industrial sovereignty. Its vertically integrated model – from recovering metals to producing finished magnets – ensures both supply security and low-carbon performance.

As Petit explained: “Magnets are critical to so many products, from cars and wind turbines to medical devices and defence systems. By building a fully European value chain, we are showing that sustainability and sovereignty can go hand in hand. Our ambition is to give European industry the confidence that it can access the magnets it needs – reliably, responsibly, and without compromise on performance.”