How Keey Aerogel is bringing low-carbon insulation home to Europe

Keey Aerogel has developed Europe’s first sustainable aerogel and is now preparing for full industrial deployment.

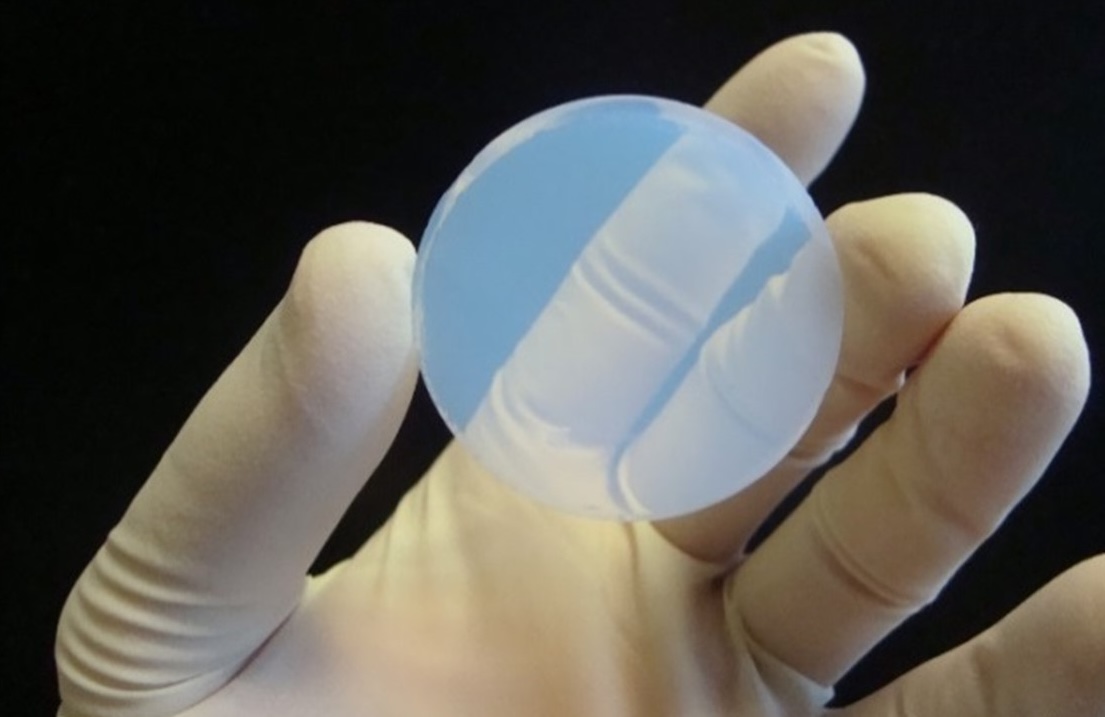

Solid state aerogel. Image: Keey Aerogel

Aerogel is one of the world’s most powerful insulation materials–ultra-lightweight, highly porous, and exceptionally efficient. It plays a crucial role in improving energy efficiency and fire safety across industries from construction and energy to aerospace, and, increasingly, electric vehicle batteries, where it helps improve durability and reduce fire risk.

Until now, European industries have relied heavily on aerogel imported from the US and Asia–supply chains that are carbon-intensive, costly, and vulnerable to disruption.

But Keey Aerogel is poised to change that. Earlier this year, the French company secured €18 million in Series A funding to accelerate its mission to become Europe’s leading aerogel producer, delivering a cost-effective, low-carbon alternative to imported aerogel.

“Our goal is to become Europe’s leading producer of aerogel and the world’s first manufacturer of green aerogel,” says Francisco Ruiz, Founder and CTO of Keey Aerogel.

Keey Aerogel was recently awarded Scale-up of the Year by Ernst & Young for the eastern region, France, a recognition that underlines both the disruptive potential of green aerogel and the determination of the team bringing it to market.

From research to pilot production

Founded in 2015, Keey Aerogel developed and patented a breakthrough process that dramatically lowers the cost and environmental footprint of aerogel production.

Unlike conventional methods–which rely on energy-intensive processes and single-use solvents–Keey Aerogel’s approach uses construction and demolition waste as feedstock, consumes less energy, and fully recycles solvents like ethanol and CO₂ in a closed loop. The result is an ecological aerogel that combines the performance of traditional aerogel with a fraction of the carbon impact.

EIT RawMaterials supported the company from its earliest stages - first through the Business Idea Competition in 2016, then the 2019 Booster programme and business and entrepreneurship coaching. This support helped Keey Aerogel refine its business plan, engage industrial partners, and validate its technology at pilot scale.

Keey Aerogel Founder & CTO Francisco Ruiz at KA's pilot plant in Habsheim. Image: Keey Aerogel

“These programmes gave us visibility, expert guidance, and access to a strong European innovation network–including partners like TECNALIA, the largest applied research and technological development centre in Spain,” says Francisco Ruiz, Founder and CTO of Keey Aerogel.

“Funding from EIT RawMaterials was critical in helping us scale from laboratory prototypes to pilot production. It allowed us to prove industrial feasibility, strengthen our intellectual property, and lay the groundwork for large-scale commercialisation.”

Building a European aerogel industry

With this foundation in place, Keey Aerogel has been accelerating toward industrial scale.

In January 2025, the company closed a €18 million Series A funding round led by Bpifrance’s SPI 2 Fund under the France 2030 programme, with participation from WIND, Capital Grand Est, and NCITY. The investment will finance a second production facility in the Grand Est region which, once complete, will significantly increase production capacity, enabling Keey to supply key European markets with locally produced, low-carbon aerogel.

But Keey Aerogel’s vision goes far beyond a single production site. The company plans to replicate its model across Europe, creating a network of decentralised plants that transform local construction waste into high-performance insulation. This will cut transport emissions, enable local sourcing, and secure Europe’s access to a material that is becoming critical for energy efficiency and safety.

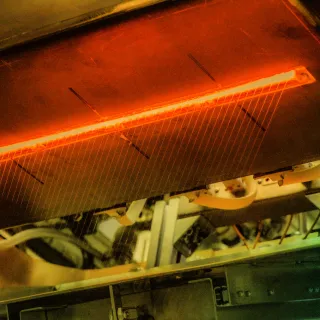

Aerogel has extremely low thermal conductivity. Here it shields the top from the flame’s heat and repels water on its surface. Image: Keey Aerogel

Along with supporting startups in the advanced materials sector, EIT RawMaterials also leads the European Advanced Materials Academy. The Academy equips learners with advanced materials skills for today’s jobs by offering a comprehensive portfolio of multilingual, modular, and accredited learning programmes across the advanced materials value chain.

To find out more visit the European Advanced Materials Academy Website.