EIT RawMaterials-backed defence tech startup Fibrecoat among Time Magazine’s Best Inventions 2025

From the university lab to TIME Magazine’s Best Inventions list, FibreCoat’s breakthrough radar-absorbing material is reshaping Europe’s defence and aerospace sectors.

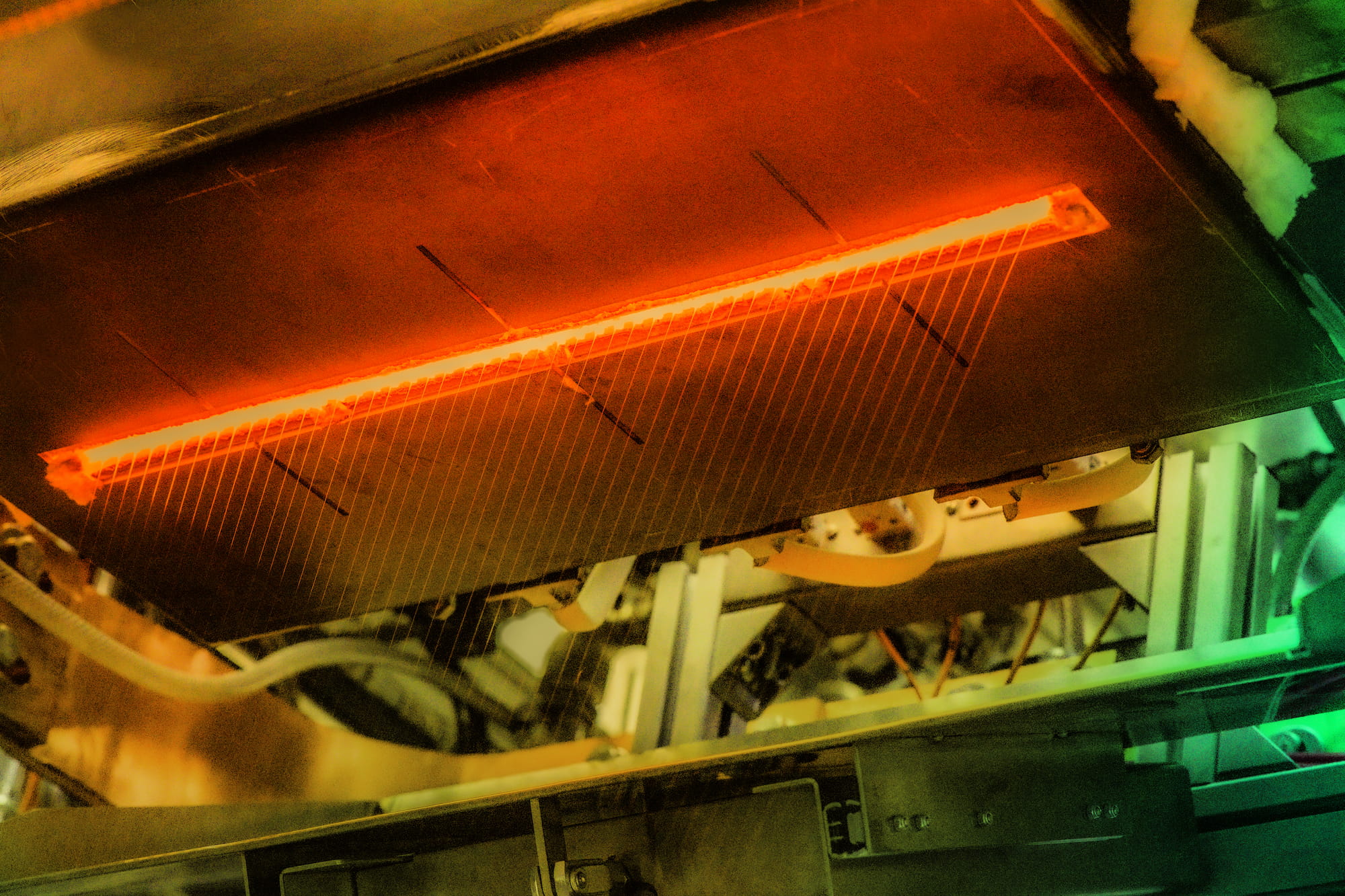

FibreCoat, supported by EIT RawMaterials in 2021, has been recognised by TIME Magazine as one of the Best Inventions of 2025. Its breakthrough Radar Absorbing Material (RAM) combines metal-coated fibres with plastics to create lightweight, customisable composites that can make aircraft and other objects undetectable by radar.

Behind this achievement is a story of persistence and reinvention. We spoke with FibreCoat’s founder and CEO, Robert Brüll, about the startup's journey from a university lab to international recognition, how its technology is reshaping the defence and aerospace sectors, and what comes next.

Robert Bruell, CEO and Co-founder of Fibrecoat

EIT RawMaterials: Congratulations on being named one of TIME Magazine’s 100 Best Inventions of 2025. That’s an incredible achievement. What does this recognition mean for Fibrecoat?

Robert Brüll: It’s a great honour to be part of that list. When I look at the other inventions featured, major innovations like Anthropic Claude Sonnet 4 and Nvidia DGX Spark, it feels incredible to see our name among them. As a small materials startup working in a niche field, this recognition gives us valuable visibility and might connect us with customers we hadn’t anticipated. It’s also a huge success for our team. Everyone feels proud and energised as we head toward the end of the year.

EIT RawMaterials: FibreCoat started as a research project at Aachen University, and now it's growing into a deep-tech company. What has the journey been like?

Brüll: We spun out from Aachen University, but our story started in 2014. The idea came to me to make fibre-reinforced plastics more affordable by coating polymers onto glass fibres that could be directly processed into finished products. Together with my co-founder, Alexander Lüking, we brought the concept from the lab to pilot scale. By 2018, the process was working well, but we got frustrated seeing the industry move so slowly. Companies would buy university innovations and then put them in a drawer instead of industrialising them. So, we said, “Let’s do it ourselves.” In 2020, with Germany’s EXIST grant and our third co-founder, Richard Haas, we launched FibreCoat.

Then, COVID hit. Our polymer research had to stop because chemists couldn’t work from home, and we were dependent on specific polymers that became hard to source. Therefore, we pivoted to metal coating. When the war in Ukraine caused energy costs to soar in Germany, we quickly relocated production to Georgia. In 2023, we received our first major order—around 50 tonnes—and continued growing. By the end of last year, we managed to raise another €20 million to expand our production in the defence sector. We have a strong, adaptable team and what I like to call 'smart naivety': we believe in what we do, but we also listen and adapt when the world changes.

EIT RawMaterials: How has the EIT RawMaterials Booster Programme supported you on this journey?

Brüll: In 2021, we were in a foggy phase. The support from EIT RawMaterials helped us bridge a dry period between investments and gave us the opportunity to explore new markets and networks. The materials world is a small, tight-knit community, and having access to that is a big deal.

As a first-time founder, you often hear advice from incubators meant for software or consumer startups. But the materials world is completely different. We don’t talk about bringing 10,000 people onto a platform; we talk about working with just a few customers at first and producing materials by the tonne. That’s where EIT RawMaterials helped: connecting us with investors who understand deep tech and materials, providing valuable feedback, and helping us navigate the nuances of fundraising in this industry.

Brüll speaking at Investor Day during the EIT RawMaterials Summit, May 2025. Photo: EIT RawMaterials

EIT RawMaterials: What makes FibreCoat’s radar-absorbing material a breakthrough, and why is it particularly important for the defence and space industries in Europe right now?

Brüll: Our radar-absorbing materials are used to shield fighter jets, drones, and satellites from being detected by radar. Traditional solutions are often bulky foams or paints that degrade over time and need constant reapplication, which is costly and not sustainable for aircraft or satellites. Our technology combines coated fibres with plastics to create lightweight, high-performance plates that absorb a much broader range of radar frequencies than conventional materials. The design is fully customisable based on the application, the radar type, or the radiation.

FibreCoat’s Radar Absorbing Material (RAM) is a lightweight composite made from ultra-thin coated fibres. Photo: FibreCoat

EIT RawMaterials: There is a growing urgency across Europe to reduce dependency on imported raw materials. How does FibreCoat help in that regard?

Brüll: For the defence and space industries, secure and independent supply chains are critical. Our AluCoat product is a good example of how we approach this—it combines the strength of glass with the conductivity of aluminium, creating a new class of high-performance materials made from resources available in Europe. This means we can produce them more affordably without relying on imports. We also build our own production lines so we can set up local manufacturing quickly for our partners, giving them control over production and shielding them from global disruptions

.

EIT RawMaterials: What’s next for FibreCoat?

Brüll: We’re pushing new products for the defence industry, including projects to supply NATO and Ukraine, and working to join the European Defence Network to bring more innovation into Europe’s defence sector. On the space side, we recently won the INNOspace Masters competition, a major German programme in collaboration with the European Space Agency. Next year, our radiation-absorbing materials will be used on a satellite launching into space for the first time. We're scaling globally with production lines planned for new markets and targeting civilian markets long-term. It’ll take patience, but in the materials world, patience is the name of the game.

About Robert Brüll

Originally from Romania, Robert Brüll studied at RWTH Aachen University. With a background in composites and economics, he began his PhD in 2014 and later became Head of Technical Fibres. At FibreCoat, he and his team industrialised cost-effective high-performance materials in record time. He is active in the start-up community and is an advocate for better founder conditions.