UP Catalyst: Transforming Carbon Emissions into Sustainable Graphite

The Estonian startup recently launched its Generation 2 container reactor, a major milestone in providing the European electric vehicle industry with sustainable battery graphite and carbon nanomaterials while reducing CO2 emissions.

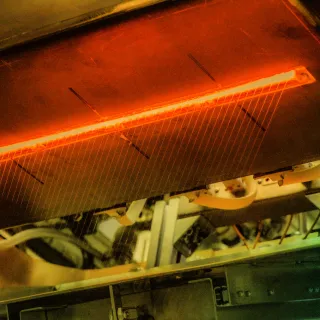

Photo: UP Catalyst with the Generation 2 pilot container reactor, developed under the CO2Carbon Project funded by the EIT RawMaterials. Photo credit: Arno Mikkor.

UP Catalyst’s Generation 2 reactor was developed under the CO2Carbon consortium funded by the EIT RawMaterials KAVA 8 Call for Upscaling Projects, which supports validated technologies that need further development—such as testing, demonstration, or scaling—to accelerate their market launch.

UP Catalysts innovation has revolutionised graphite production by developing a process that captures industrial CO2 emissions and converts them into sustainable graphite and other carbon nanomaterials. Addressing Europe’s reliance on imported graphite for EV batteries, the breakthrough won the World Economic Forum’s Carbon Capture and Utilisation Challenge in December 2024.

The Generation 2 reactor represents a significant step forward in scaling up this technology, which utilises a molten salt carbon capture and electrochemical transformation (MSCC-ET) method to reprocess CO2 from heavy industry emitters. It was achieved through collaborative efforts within the CO2Carbon consortium, supported by EIT RawMaterials.

"EIT RawMaterials enabled and facilitated our collaboration with industry and academic partners,” said Dr. Einar Karu, Vice President of Technology, UP Catalyst. “Without this support, the collaboration would have been hard to establish.”

Key contributors included Riga Technical University and the Research Institute of Sweden, both of which played crucial roles in the reactor’s design and construction. The University of Bologna was responsible for material characterisation. Additionally, UniverCell, a German maker of battery electrodes and cells, and Bettery, an Italian startup backed by EIT RawMaterials and developing a green liquid battery, tested battery cells made with CO₂-derived carbon materials.

“This breakthrough is a step closer to securing a low-cost, high-purity, local supply of critical battery raw materials in Europe. This technology allows Europe’s EV industry to reduce dependency on foreign imports while also decarbonising,” added Dr. Karu.

Dr. Einar Karu, Vice President of Technology at UP Catalyst, presents the graphite produced through UP Catalyst’s technology. Photo credit: Peeter Paaver

From university research to scalable Innovation

Born out of a university research lab, UP Catalyst was co-founded by Gary Urb, Ivar Kruusenberg, Kätlin Kaare, and Sander Ratso, driven by their mission to repurpose waste into sustainable resources. "Our idea grew out of the pain we had as researchers—to give unwanted waste products a green purpose," explained Gary Urb, CEO of UP Catalyst.

EIT RawMaterials has been a steadfast supporter of the startup from its early days, offering funding and expert guidance through the Jumpstarter and Accelerator programmes.

“We saw the potential of UP Catalyst’s brilliant team and material innovation approach from the very beginning,” said Tina Benda, RIS Manager of EIT RawMaterials. “This startup is a fantastic example of the transformative approaches needed to build a resilient European industry while achieving decarbonisation goals, and the partnership approach we take at EIT RawMaterials to support breakthrough innovations from idea to impact.”

UP Catalyst’s technology produces graphite that consumes more carbon than it emits. The Generation 2 reactor removes 3.7 tons of industrial CO2 emissions for every ton of critical battery raw materials it produces. This is a stark contrast to traditional graphite production, which is highly carbon intensive and can contribute up to 40%1 of a battery’s carbon footprint.

Vision for the future

The startup is not resting on its laurels. It is on track to finalise the construction of its Generation 3 reactor in 2025, which will produce ten times more material than its predecessor.

UP Catalyst aims to establish a large-scale industrial facility capable of producing 60,000 tons of carbon materials annually by 2030, sufficient to manufacture batteries for 4 million EV cars. The startup is poised to become a cornerstone of Europe’s strategy to develop a circular and sustainable battery supply chain.

The EIT RawMaterials KAVA 13 Call for Upscaling projects will open soon, find out more here. Want to know more about our funding opportunities then click here.