How Novana’s Circular Vanadium Model is Revolutionising the Raw Materials Recovery in Europe

Interview with Johanna Lamminen, CEO, Novana

A transformative shift from a traditional linear economy to a circular, green economy is essential for Europe to achieve carbon neutrality by 2050. Meeting the raw materials demand for the green transition while maintaining industrial competitiveness requires embracing circular strategies that prioritize reuse, recycling, and remanufacturing.

As a major European impact investor, EIT RawMaterials invests in pioneering raw materials projects like Novana, which is positioned to become Europe’s first carbon-neutral vanadium producer with a fully circular operation.

We spoke to Johanna Lamminen, CEO, Novana about the importance of vanadium for the steel industry, why vanadium is so essential for the energy transition, and how the company’s innovative model is redefining the raw materials industry in Europe.

EIT RawMaterials: Why is vanadium such a critical material for Europe’s energy transition and the green steel industry?

Johanna Lamminen: Vanadium is important for producing high-strength steel alloys, with Ferrovanadium commonly used in steel manufacturing to increase strength. It is also needed in specialty alloys for defense and aerospace applications. Vanadium demand in steel production is expected to continue growing going forward, driven by increasing vanadium intensity in steel production.

Vanadium pentoxide is a key ingredient for producing vanadium electrolyte, which is used in vanadium flow batteries (VFBs). These batteries require a high-purity product to maximize their efficiency and extend their lifespan. As renewable energy sources like solar and wind power become more widespread, there is a growing need for large, scalable, and flexible energy storage solutions, promoting the adoption of VFB technology.

VFB demand in Western Europe is expected to grow at a CAGR of over 50% in the next decade. This view is supported by the International Energy Agency (IEA)’s World Energy Outlook 2023 and the calculation by International Monetary Fund. According to the IEA’s scenario for achieving net-zero emissions, vanadium demand is expected to rise significantly by 2050.

EIT RawMaterials: What makes Novana’s process innovative and carbon-neutral?

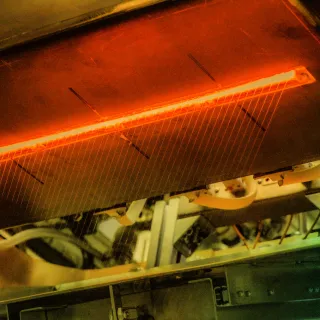

Lamminen: Instead of mining for resources, we at Novana recycle industrial side streams. Our innovative process uses carbon dioxide (CO2) to create a solution that releases vanadium from the slag while leaving other metals behind. This allows us to recover vanadium efficiently and sequester CO2 into the residue, which can be reused in cement, land reclamation, and plastics, ensuring that no waste is produced.

What really sets us apart is that carbon dioxide is the only reagent we consume in the process. For every tonne of BOF (basic oxygen furnace) slag processed, we sequester about 250 kg of CO2. Our innovative process also allows us to recycle process water multiple times, saving water and reagents while minimising waste. By the final steps, which use industry-standard operations, the high-purity vanadium solution we have generated ensures a high-quality final product.

EIT RawMaterials: Why is now the right time for Novana’s vanadium recovery project?

Lamminen: Europe is dependent on vanadium imports, mainly from China and Russia, and lacks domestic production. We’re ready to fill this gap with all environmental permits and agreements in place. When in production, Novana would become an important “domestic” supplier with significant volume to the European market. There are over two million tonnes of steel slag available across three Scandinavian SSAB sites, ready to be processed into more usable forms while recovering vanadium.

EIT RawMaterials: What are the benefits of operating in Pori, Finland, and how do your local partnerships support sustainability and the circular economy?

Lamminen: Pori offers several advantages, including its proximity to an ice-free, deepwater harbor, which ensures efficient logistics for both raw materials and finished products. Finland’s strong renewable energy sector is another benefit, and we have access to it as well. The Pori area is known for very talented and skilled people and a history of having chemical process technology companies. VRP will create opportunities for graduates and support local industries.

Partnerships in the area also enhance Novana’s sustainability initiatives. ESL Shipping offers low-emission transport options. The CO₂ sequestered provides a local pathway for significant quantity of discharged CO2 off-gas. Novana’s approach aligns with European Union initiatives such as the Green Deal and the Critical Raw Materials Act, contributing to the circular economy and meeting international sustainability standards like the Equator Principles and the Task Force on Climate-related Financial Disclosures (TCFD). The Environmental Impact Assessment (EIA) was also completed in January 2022.

EIT RawMaterials: How has EIT RawMaterials' support helped Novana?

Lamminen: EIT RawMaterials has played a pivotal role in Novana’s success. We have received grant funding through the Booster Call and EIT RawMaterials is also helping us and our advisor SEB in the equity raising process. We have been receiving good ideas and contracts from EIT RawMaterials’ experts and their networks.

EIT RawMaterials: What is the financial growth potential of the new plant, and what’s next for investment?

Lamminen: We will produce approximately 9000 tons of very high purity vanadium pentoxide annually, and that would be close to 4% of the total annual global production. Operating within the lowest cost quartile ensures robust cash flow and significantly reduces investment risks. Looking ahead, there is potential to establish 2–3 similar plants worldwide, and we are naturally exploring those opportunities as well.

About Johanna Lamminen

Johanna Lamminen is an experienced business leader and board professional with a distinguished career in executive roles across various industries. As the CEO of Novana, she brings a wealth of expertise in corporate leadership, strategic management, and financial operations. Her previous roles include serving as CEO of Gasum, CEO and CFO of Danske Bank Finland, and CFO and Deputy CEO of Evli Bank.

Find out more about the EIT RawMaterials funding opportunities