Why Europe must act now to change public perception of mining

Why Europe must act now to change public perception of mining

The Critical Raw Materials Act (CRMA) sets the target for the EU to extract 10 percent of its annual demand for key raw materials needs by 2030. To meet this goal, Europe must significantly boost its metal extraction and refining capabilities. According to Eurometaux, meeting the EU’s 2030 raw material goals will require the opening of at least 10 new mines, 15 processing plants, and 15 recycling plants in the coming years. However, overcoming public opposition, especially for new mines, remains a crucial challenge to achieving these goals.

We spoke to Peter Tom Jones, Director of the KU Leuven Institute for Sustainable Metals and Minerals and documentary maker, about the importance of gaining public support for getting responsible mining projects up and running in Europe.

EIT RawMaterials: Which key challenges is the European mining sector currently facing?

Peter Tom Jones: One of the most daunting challenges for the EU mining sector is the reputational and perception issues it faces. What people often don’t realise is that everything around us that wasn’t born or grown was once mined. Without the mining of metals and minerals, there would be no buildings, no bridges, no railway tracks, no fridges, no smartphones. And, looking towards the future, without (mined) metals we cannot manufacture the cleantech products — from wind turbines to solar panels, heat pumps, electrolysers, batteries and electric buses — that are needed in ample quantities to drive the transition to a climate-neutral economy.

However, when it comes to mining, many people don’t grasp the difference between a 20th century, dirty and dangerous coal mine and an ultramodern, automated copper-nickel mine running on renewable energy. The former fuels the global climate crisis, while the latter is part of the solution.

European mining companies have boosted their ESG standards significantly in recent years and are serious about becoming climate-neutral in their own operations.

EIT RawMaterials: Can you give us some examples of European mining companies which are following high ESG standards?

Peter Tom Jones: The Nordic countries lead the way here, which is made easier for them as they have access to abundant, relatively cheap, green electricity. Their improved waste management and water stewardship are key as well.

We are seeing a transition to safer, more automated working conditions and mine workers in Northern Europe, in particular, also receive very good salaries, prompting even teachers and nurses to move to a career in mining.

Also, companies now realise that building up long-term relationships with the local communities is not merely an ideal to aim for, but a fundamental necessity. Maintaining a continuous dialogue with the communities, employing and training local people, and integrating local businesses and suppliers are all part of the responsible mining model. Despite these advancements, public perception hasn’t caught up. The recent nationwide protests we have seen in Serbia, in response to Rio Tinto’s planned underground lithium mine, speak for themselves.

EIT RawMaterials: Do we need a strategy at European Commission and Member State levels to educate local audiences and increase social acceptance of mining?

Peter Tom Jones: Absolutely, this is of utmost importance. We need concerted campaigns to educate and inform the general public properly about the responsible mining and refining of metals needed to drive the transition to a net-zero greenhouse gas emission scenario by 2050. Without metals, there is no cleantech. Without cleantech, there is no climate transition – it’s as simple as that.

We also need to explain the importance of developing this sector in Europe in order to avoid critical and dangerous dependencies on countries that do not share our democratic values and high environmental, social and governance (ESG) standards.

Failing at this will have hard-core social repercussions; without a concerted industrial strategy to develop made-in-Europe, mine-to-cleantech value chains, we will see the gradual de-industrialisation and impoverishment of Europe.

That’s why I am convinced that we need to engage in storytelling that can explain these basic ideas to as many people and policymakers as possible. That’s exactly why I decided to start presenting and making more fact-based documentaries about the responsible mining and refining of metals in Europe.

Our next documentary “Europe’s Lithium Paradox”, coming in 2025, will take us to Portugal and Serbia, where two of the most important lithium mining projects in Europe are trying to get started. However, both are confronted with major environmental opposition. The paradox here is: we need lithium for the climate transition, we have it in our bedrock, but we fail to recover it because of local environmental opposition. The result is that Europe is left in a dire dependency situation, while we keep importing lithium (products) that were produced in ESG-unfriendly circumstances. It’s a lose-lose situation which is mind-boggling to me.

EIT RawMaterials: One of the major advantages of the CRMA is that it introduces quicker permitting times for strategic mining projects. Do you think that failure to gain civil society’s support could still significantly hinder the process of opening new mines?

Peter Tom Jones: The success of the CRMA hinges on the endorsement and implementation of a number of strategic mining, refining and recycling projects. However, opposition to energy-transition metal mining projects is definitely the Achilles heel of the CRMA. If we don’t make progress in this area, I believe the CRMA goals will remain pipe dreams.

In many concrete cases, we see that the local opposition is fueled by highly vocal (inter)national anti-mining activist groups. As a result, one could falsely get the feeling that all local people object to a specific mining project, whereas in reality there might be a silent majority that is actually in favour. How the European Commission reacts to such pressure will be crucial for maintaining confidence in the CRMA’s “strategic projects”. Will the European Commission allow vocal minorities to hijack the process, or will it ensure that common sense and the overriding public interest prevail?

I would urge the fact-based, rational side of the broad environmental movement to engage in a dialogue with the Raw Materials Community and to recognise that it would be hypocritical to block responsible mining projects in Europe that respect the highest possible ESG standards, while we continue to import batteries or other cleantech products produced with materials obtained from dirty and unsafe mining projects from outside Europe.

We really need to consider these kind of global climate, biodiversity and social trade-offs. Policymakers, state agencies, consumers and citizens alike all need to understand that we need a shift in mindset: from Not In My Back Yard to BIMBY: Better in My Back Yard. But the window of opportunity is rapidly closing. 2030 is just 5 years away.

EIT RawMaterials: What is your ideal vision for the future of Europe’s mining sector?

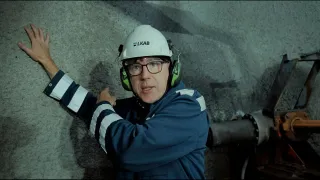

Peter Tom Jones: A community-centric, benefit-sharing, ESG-proof, responsible mining paradigm. We already see parts of that in the Nordic countries with companies such as LKAB and Boliden. The mine-of-the-future is largely automated and completely safe for its employees while operating in a 100 percent climate-neutral way using local renewable electricity, with a near-circular water loop and an advanced dry stacking tailings management in which also part of the tailings is reused in low-carbon building materials.

This kind of mine will also target a “nature-positive” impact, which incorporates biodiversity-compensating and progressive nature-reclaiming measures during the lifetime of the mine, with a closure plan that restores the environment as closely as possible to its original ecosystem. Local communities will be active stakeholders, benefiting directly from the mine’s activities through local employment and business integration. For instance, local farmers can sell their food products to the mining company’s cafeteria, as is targeted in the Jadar and Mina do Barroso projects in Serbia and Portugal.

EIT RawMaterials: What roles do education and training programmes across Europe play in preparing the next generation of mining professionals?

Peter Tom Jones: It’s crucial not to view mining in isolation, but rather as connected to the downstream processing and refining. That’s what I like about initiatives such as EIT Raw Materials and Prometia.

The mine worker of the future will need more digital skills rather than sheer muscular strength. This also facilitates the diversification of the working environment in mining companies, as we can see in the Nordic examples of LKAB and Boliden.

As machine learning and digital AI technologies increasingly find their way into the mining sector, adapted educational programmes will be essential.

EIT RawMaterials: The pick and shovel logo, once an iconic symbol of mining, is now fundamentally outdated and should be retired. What do you think the new icon should be?

Peter Tom Jones: A modern mine worker is not digging into rocks with a pick and shovel but operates a hi-tech mining device with a Playstation controller while sitting in a nice, air-conditioned control room. So, let’s use a Playstation-like icon for the future.

Peter Tom Jones is the Director of the KU Leuven Institute for Sustainable Metals and Minerals (SIM²), leading a team of 400 researchers focused on sustainable energy-transition metals. With over 20 years of experience, Jones completed his PhD in Metallurgy at KU Leuven in 2001 and co-founded the SOLVOMET Research & Innovation Centre, specializing in hydrometallurgy. He has coordinated or partnered in over 30 EU-funded projects on sustainable metallurgy and critical raw materials. Jones is also the author of several books on climate and circular economy and produces documentaries on Europe’s mine-to-cleantech value chains.

Jones was a speaker during the session “Race to achieve energy security” at this year’s Raw Materials Summit, organised by EIT RawMaterials. This OpEd is based on his contributions. The next summit is scheduled for May 13-15, 2025. www.eitrmsummit.com