Project duration: 1 January 2020 – 31 December 2022

Objective

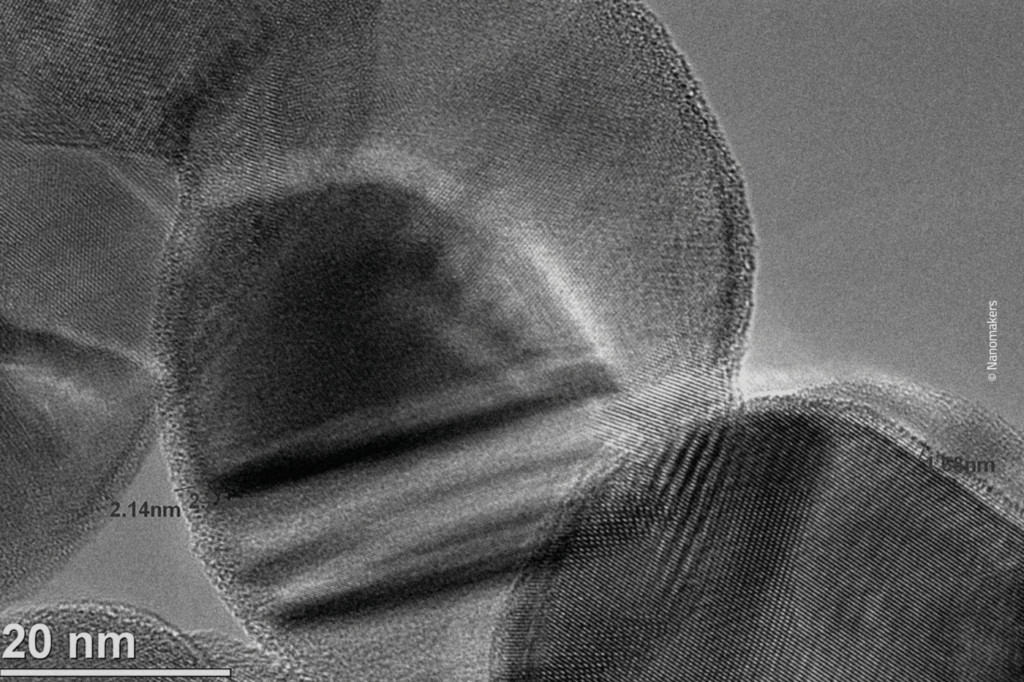

The commercialization of SiC fibers in Europe by the company BJS is prepared. SiC fibers are used in CMC materials, which will substitute nickel-superalloys in future aircraft turbines. Using CMC enables significant reductions in CO2, NOx and noise emissions while saving about 2/3 of weight (important to reach the EU FLIGHTPASS 2050 goals). Additionally, the use of critical raw materials (e.g. V, Co, Y, Nb, Ru, Hf, Ta, W) will be avoided.

The solution (technology)

The project intends to support the commercialization of SiC fibers for the European market. The SiC fibers are used in Ceramic Matrix Composites, which aim to replace Ni-base superalloys in the next generation of aero-engines. By doing so, the use of critical elements like V, Co, Y, Nb, Ru, Hf, Ta, W is avoided and significant weight reductions to 1/3 can be achieved. Additionally, an increase in operation temperature will be possible leading to an increase in energy efficiency and cleaner combustion. Together with the weight savings, this will play an important role to achieve the reductions in climate-damaging gas emissions set by the European Union in the Flightpass 2050 goals.

The development of SiC fibers constitutes a high technological barrier. Currently, there are only two producers in Japan and one production is ramped-up in the USA at the moment. Due to limited production capacity and export-control barriers, a secured supply of SiC fibers to Europe in large enough quantities is not foreseeable. For this reason, the development of CMC technology in Europe is massively hindered.

The SiC fiber technology has been developed to TRL5 by part of the consortium. On this basis, a pilot fiber plant has been defined and is currently built-up with a budget of 20 M€. Commissioning of the pilot fiber plant is planned for mid-2019 allowing to raise the TRL to 7-8. The project objective is to support the commercialization of SiC fibers in Europe in order to enable large enough and secured supply of high-quality SiC fibers to the European market. To achieve this, the project aims to establish the precursor supply, upscale SiC fiber technology to TRL 7-8 and qualify the fibers in CMC technology.

Partnership

- ABCR Labs, Spain

- BJS Ceramics GmbH, Germany

- Netherlands Aerospace Center, Netherlands

- Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e.V. (Fraunhofer) (Lead Partner), Germany