Three times stronger 3D printing materials with new additives

The mechanical durability of 3D printing materials increases with 200 percent when added the novel 3D Strong additives shows test results from the laboratory of Riga Technical University.

We are thrilled with the results and can’t wait to test our additives in real life. It’s a breakpoint in the 3D printing industry to change the use of technology from prototyping to real industrial manufacturing. The good news is that companies don’t need to change any equipment to be able to use our additives.

Maryna Petrychenko, CEO at 3D Strong

Currently, the Latvian start-up company 3D Strong is running pilot tests with producers of 3D printing materials in the U.S. and are preparing for pre-R&D with producers of chemicals in EU.

From the time of our launch, we have been focusing on creating additive materials based on modified carbon nanotubes, CNTs, that are of great interest due their unique properties, such as extreme strength, special electrical properties, high efficiency when used as conductors of heat and for corrosion resistance.

Maryna Petrychenko, CEO at 3D Strong

No change in production equipment needed

The CNTs can impart new properties to existing materials with only a small addition and are indispensable in the design of new composite materials, including those based on metals, plastics, and polymers.

No change in production equipment needed

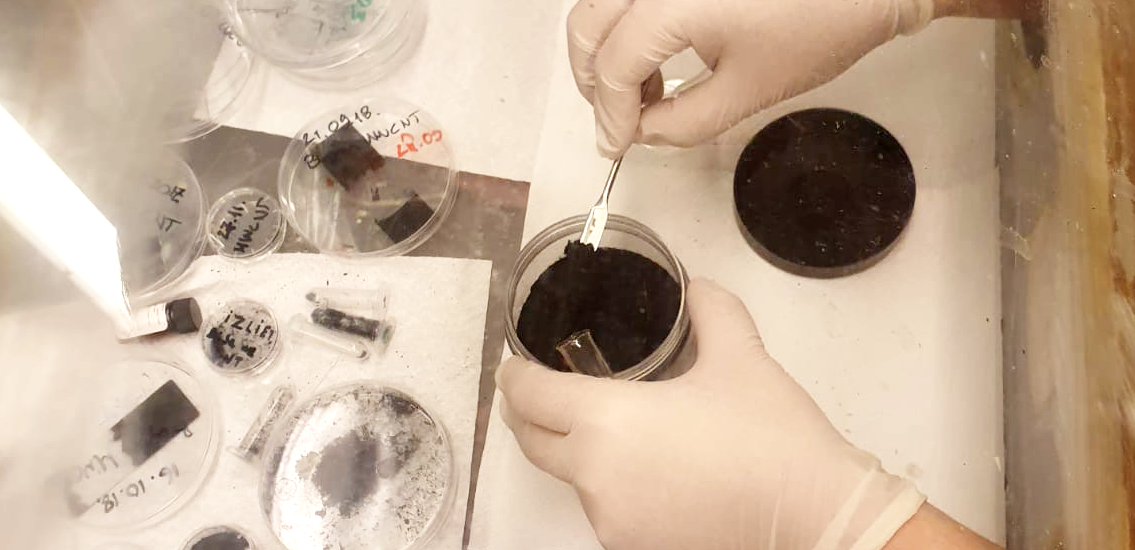

Additives that are based on carbon nanotubes, CNTs, and created by 3D Strong were added to acrylic monomer liquid that is used for 3D printing. Polymer material samples with 3D Strong additives showed excellent results in improving the mechanical characteristics of materials with an optimal concentration of CNTs.

The average tensile strength tripled (a rise by 200 percent) compared to samples without CNTs. The maximum increase is 4.4 times (340 percent). This means that dispersion of a relatively small amount of modified CNTs into 3D printing materials produces a significant increase in tensile strength, elongation at break, modulus of elasticity and/or conductivity of the 3D object by giving it unique properties due to the strong bonding of layers by means of the CNTs.

The purest product on the market

The company manufactures CNTs with their own equipment and claims a 99.9 percent purity of the materials. Other companies in the market offer CNTs with an approximate purity of 50–70 percent. Moreover, the 3D Strong team has found a way to modify and use CNTs with other chemical elements to create different applications for the market.

3D Strong’s R&D team has over 20 years of experience in nanotechnology. Currently, the team has raised $115 000 in funds. It is self-funded and has received investments from ABC Accelerator in Slovenia, Commercialization Reactor fund in Latvia and EIT RawMaterials.

Thanks to the support we have received from EIT RawMaterials, we have been able to move from the laboratory to the market. Through the EIT RawMaterials Community, we have gained important credibility for our work and access to a really good network of potential partners and customers. They believed in us and that meant a lot to us.

Maryna Korabovska, COO and Co-founder of 3D Strong

The best accelerator program for deep tech start-ups

The company was chosen to participate in the EIT RawMaterials Accelerator program that started in September 2019.

The Master classes were very good and the feedback we got from the coaches were helpful. We changed our way of thinking about business during the program, thanks to the advices we were given.

Maryna Petrychenko, CEO at 3D Strong

3D Strong has been accepted to the RM Accelerator program Phase 2 – Grow, continuing to receive coaching and support to hone their business strategy.

This is the best accelerator program in Europe for deep tech start-ups. We have participated in four or five other programs in the U.S., Slovenia, Latvia and Germany, but EIT RawMaterials Accelerator program is absolutely the best.

Maryna Petrychenko, CEO at 3D Strong