The current Li-ion battery market is mostly dominated by batteries where Critical Raw Materials (CRM) constitute the active materials.

ALIM (Advanced Lithium-metal electrodes), a project supported by EIT RawMaterials, aims to commercialise CRM-free batteries for electrical vehicles, as well as stationary applications. To do so, the consortium will work on the processing of extra-thin, pure lithium electrodes that can avoid the use of Cobalt and Graphite.

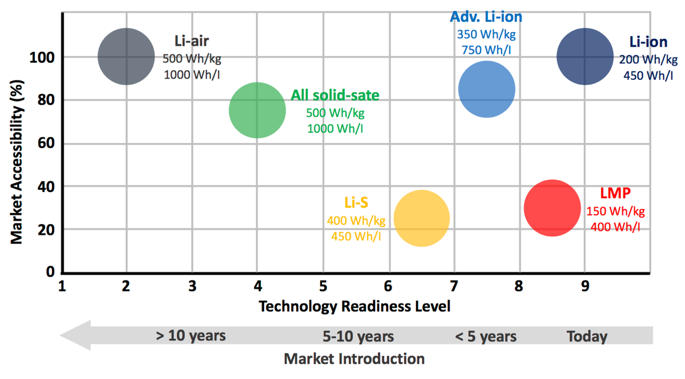

Developing better energy storage solutions is definitely a challenge for the 21st century. Between electric vehicles, renewable energy systems and expanding portable applications, there is intensive research to engineer batteries with higher capacity, along with low cost, high cyclability and greater safety (Figure 1).

Figure 1. Main battery families that are currently investigated for electro-mobility applications

The current Li-ion technology is progressively reaching its limits in terms of performances and may not fulfill all those customers and market needs (ref1). Furthermore, the active materials of such batteries rely on Critical Raw Materials (ref2), particularly Cobalt and Graphite, the supply of which could be at risk in the future. There is hence a twofold motivation in looking for alternatives beyond the established systems.

BlueSolutions already commercialises batteries under the Lithium Metal Polymer brand (LMP®), often referred to as solid-state batteries. Designed for electrical vehicles (BlueCar®, BlueBus®) and stationary applications, those have the advantage of already circumventing the use of Cobalt. To further boost their performance, Lithium metal is the most promising material to replace Graphite.

The ALIM project aims at mastering the production process of extra-thin, pure lithium electrodes. To this purpose, the consortium will benefit from the strong background of Bühler Redex in rolling mills and high precisions machines, as well as from the experience of CEA and Uppsala university in the field of Lithium batteries and their characterisation.

Together the consortium shall bring the 4th Generation batteries to another level of performance that will improve the autonomy of electric vehicles and increase capacity in stationary applications. Furthermore, by reducing dependency from strategic metals, the project shall, beyond competitiveness, contribute to a greater sustainability of the European battery sector, one of the goals of the newly-founded EU Battery Alliance.

Additional information

Reference 1: An overview of the developments of Li-ion technologies

Reference 2: 2017 list of Critical Raw Materials for the European Union defined by the European Commission

The members of the ALIM project consortium are:

CEA (French Alternative Energies and Atomic Energy Commission) (Lead Partner)